Our Services & Solutions

Project & Engineering Solutions to provide high-quality products and support

Pragyaa engaged in design, engineering, procurement, construction and project management of the following services across various industries.

Electro-Mechanical Works

we undertake EPC of process skids, plant maintenance & shut down work, pipeline projects (new, rerouting, modifications etc.), structural fabrication & erection, tank fabrication and erection, plant erection and commissioning, controls and electrical systems, SCADA etc.

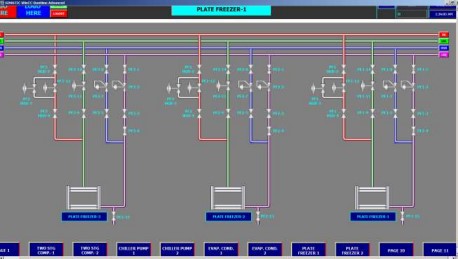

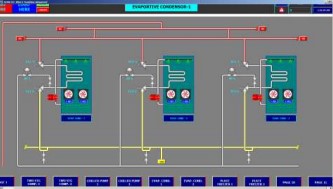

Industrial Refrigeration

Design, engineering, construction and installation of Ammonia & Freon refrigeration systems on turn key basis, including electrical substations. Our references and core competence includes automated food / fish processing, dairy, surimi or freezing plants, cold storage, racking systems, individual blast & plate freezers, ripping chambers, ice plants and accessories etc.

Plant Optimization

Introduction to proven innovative technologies for production enhancement, control system upgradation, automated plat operation, renovation and upgradation of existing plant with latest technologies.